Glass Etching, Engraving, and Cutting Machines

UV Lasers (5W, 10W, 15W) vs. JPT M8 Fiber Lasers

Laser engraving on glass has opened up exciting possibilities for hobbyists making personalized gifts and professionals offering high-end engraving services.

From custom wine glasses and awards to industrial glass components, the right laser machine can etch delicate designs with precision or even cut through glass when needed. But with several types of laser technologies available – UV “cold” lasers, CO2 lasers, and high-power fiber lasers – how do you choose the best tool for your glass projects? In this comprehensive guide, we’ll explore the types of laser machines used for glass etching, engraving, and cutting, with a special focus on UV laser engravers (in 5W, 10W, and 15W power tiers) and the latest JPT M8 fiber lasers (100W/120W) that push the boundaries of glass processing. Along the way, we’ll discuss the advantages of each system, including 3D galvo heads for curved surfaces, and what other materials you can work with.

Whether you’re a DIY hobbyist or run a professional engraving business, this guide will help you make an informed decision – and we’ll include tips, photos, and even a recommendation table to summarize our findings.

Let’s dive in!

Types of Machines for Glass Etching, Engraving, and Cutting

Laser machines have become the go-to choice for working with glass because they offer a non-contact method to create permanent marks. However, not all lasers are equal when it comes to glass. Here’s a breakdown of the main machine types and how they perform on glass:

- CO2 Lasers (10.6 μm Infrared) – These are common in sign-making and trophy engraving. A CO2 laser can etch the surface of glass by blasting the top layer, producing a frosted, matte appearance. This method is effective for simple designs or large text, but it relies on thermal shock – the IR beam heats the glass causing micro-fractures. As a result, CO2-engraved glass has a slightly rough texture and lower resolution compared to UV engraving. In fact, UV lasers can achieve marks “up to 100 times more precise” than a CO2 on glass

. CO2 engraving is simpler and can cover large areas, but the output isn’t as sharp or detailed, and very fine graphics or photos may lose clarity. Cutting glass with CO2 is generally not feasible – the beam is absorbed by glass and creates cracks rather than a clean cut (most attempts result in the glass shattering or needing a water assist). CO2 lasers are excellent for many materials (wood, acrylic, etc.), but for glass they are best suited to surface etching with moderate detail. - UV Lasers (355 nm Ultraviolet) – UV laser marking machines are the gold standard for high-precision glass engraving. The 355 nm UV beam is strongly absorbed by glass, allowing it to micro-etch the surface with minimal heat impact. This is often called “cold marking” because the UV’s high-energy photons break chemical bonds on the glass surface without significant thermal stress. The result is crisp, smooth marks that resemble a sandblasted look but with much finer detail and none of the cracking or chipping that CO2 can cause. UV lasers create a frosted white mark on glass that is smooth to the touch and highly accurate – ideal for intricate designs, photos, or small text. They are available in lower power ratings (typically 3W to 15W), which is sufficient for engraving but not for cutting through thick glass. (UV lasers can cut very thin glass or wafers in some cases, but generally these machines are used for marking and not for slicing through glass objects.) We’ll explore UV laser options in detail in the next sections.

- Fiber Lasers (1064 nm Infrared) – Fiber laser engravers are powerhouses for metals and certain plastics, but standard fiber lasers struggle with clear glass. The infrared 1064 nm beam passes through transparent glass without coupling energy, meaning it usually won’t mark or cut clear glass directly. However, recent advancements with MOPA fiber lasers (such as JPT’s M-series) have enabled high-peak-power pulses that can interact with glass in special ways. By focusing intense bursts of energy, a fiber laser can induce micro-fractures or even drill through glass. For example, the JPT M8 100W+ fiber lasers can drill holes and even cut shapes in glass by a controlled shattering process, thanks to their extremely high pulse energy. This is a very different process than the gentle surface etching of a UV laser – fiber lasers essentially ablate or fracture the glass rather than smoothly etching it. The upside is that a powerful fiber laser can cut through glass (and of course handle metal cutting/engraving too), which UV and CO2 cannot do. The downside is that the edge quality on glass may be rougher and there’s risk of cracks if not done carefully. In practice, fiber lasers are not the first choice for decorative engraving on glass (UV wins there), but they are an option for industrial tasks like drilling holes in glass or cutting very thick or hard glass that other lasers can’t handle. We will discuss the JPT M8 fiber laser capabilities later in this guide.

- Other Methods – Aside from lasers, it’s worth noting traditional glass marking methods. Mechanical engraving machines with diamond tips can scratch designs into glass, and sandblasting with stencils can etch patterns as well. These methods, however, are slower and less precise for fine detail. There are also hobbyist tricks, such as coating glass with an absorbent material (like paint or tape) and using a diode laser (450 nm blue) to indirectly etch the glass. Those techniques can work for basic designs, but they lack the consistency and quality of a purpose-built laser engraver. For the scope of this guide, we’ll focus on laser machines (UV and fiber) that offer precision and efficiency for glass work.

Now that we’ve surveyed the landscape, let’s zero in on UV laser engraving machines – the preferred choice for detailed glass etching – and compare the 5W, 10W, and 15W models including their strengths and limitations.

UV Laser Engraving Machines for Glass

UV lasers operate at a wavelength of 355 nm (in the ultraviolet spectrum), which gives them two key advantages for glass engraving: a very small focused spot and a “cold” marking process. The spot size of a UV laser can be just a few tens of microns, allowing for extremely fine detail. And because the UV photon energy is high, it can mark materials through a photochemical effect rather than just heat – this means minimal heat distortion or charring on the material. In practical terms, a UV laser can etch a logo, photograph, or intricate pattern on glass such that the mark is smooth (no glass shards), precise, and doesn’t weaken the object with cracks. The trade-off is that UV lasers are lower in power and slower at engraving compared to CO2 or fiber on other materials. They excel at quality over speed.

UV laser machines for marking typically come in a few power tiers. Let’s look at three common classes – 5W, 10W, and 15W UV lasers – to see how each one fits different needs. We’ll also discuss how features like cooling and lens size come into play, and include calls to action if you’re considering a purchase at each level.

5W UV Laser Engravers: Precision on a Budget

Entry-level UV laser engravers around 5 watts output are popular among hobbyists and small businesses for their high precision and lower cost. A 5W UV laser is powerful enough to mark glass, plastics, ceramics, etc. with fine detail, but being the lowest power tier, it has a few limitations to be aware of:

- Best for Small Areas: Most 5W UV machines are set up with a standard marking field around 100×100 mm to 150×150 mm. You can install larger lenses (some support up to ~300×300 mm area), but for glass work it’s recommended to stay at or below 150×150 mm area for optimal power density. In fact, Haotian’s guidance for its 5W UV laser is not to exceed a 150 mm square when engraving glass, because beyond that the energy gets spread too thin and results may fade at the edges. So, a 5W UV is ideal for engraving logos, text, or graphics on relatively small items (think jewelry, phone backplates, glassware, etc.). If you need to cover a large panel or multiple objects in one go, a higher power laser (or dividing the job into sections) will be better.

- Slower Engraving Speeds: With lower wattage, you’ll engrave more slowly to get a good result on glass. For example, one 5W UV machine spec notes a maximum marking speed of 5000 mm/s, but cautions that for glass you should run much slower – on the order of 200 mm/s – to avoid skipping or faint marking. This is because glass needs a certain dwell time of the UV beam to create a visible frost; going too fast, the 5W beam won’t have enough energy per spot. In practice, 5W users often run multiple passes or slower speeds for glass, especially if a deeper or more opaque mark is desired. It’s a perfect trade-off for prototypes or custom gifts (where quality matters more than throughput), but less ideal if you have to crank out dozens of items per hour.

- Air-Cooled Simplicity: One advantage of many 5W UV lasers is that they are air-cooled units. The laser source generates less heat, so it can use fans/heat sinks instead of requiring an external water chiller. This makes the machine more compact and easier to maintain – a 5W UV laser system often comes as a desktop-sized galvo engraver that plugs into a standard outlet. The Haotian HT-5, for instance, is a 5W UV galvo laser that is air-cooled. Air cooling is convenient, though you have the option (with some vendors) to add water cooling for improved stability if running the laser for long periods. Generally, 5W UV machines are perfectly fine air-cooled for light to medium use.

- Ultra-Fine Detail: Despite being “entry level” in power, 5W UV lasers offer outstanding detail on glass and other substrates. Because of the small beam spot, they can achieve tiny text (≤0.15 mm characters) and line widths down to 0.01 mm. This means you can engrave things like photographs, QR codes, or intricate artwork on glass that would be impossible with a CO2 laser. The low thermal impact also ensures even very thin or delicate items (like a glass ornament or a microscope slide) won’t crack from the engraving process. In short, 5W UV lasers are all about precision. If you’re a hobbyist wanting to personalize gifts or a startup offering custom engraving on demand, a 5W UV machine is a budget-friendly way to get professional-quality results.

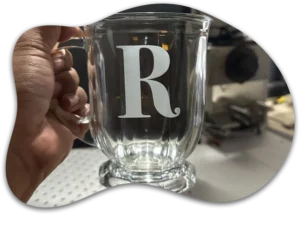

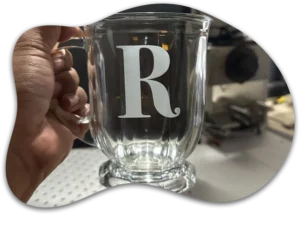

5W UV: Ready to start engraving glass with precision? Consider the Haotian HT-5 5W UV Galvo Laser, a compact air-cooled UV engraver. It offers a 150×150 mm working area (expandable if needed) and delivers ultra-fine marking on glass, plastic, and more, all at an accessible price point (around $5K including rotary and safety gear). It’s an excellent entry-level machine to kickstart your laser engraving projects with confidence.

Example of a 5W UV laser engraving machine (Haotian HT-5 UV Galvo). This air-cooled desktop unit uses a 355 nm UV laser source (right-hand box) and a high-speed galvanometer head (left) to mark glass and other delicate materials with ultra-fine detail.

10W UV Lasers: Mid-Range Powerhouses (Water-Cooled)

Stepping up to a 10W UV laser brings a significant boost in engraving capability. These mid-tier UV lasers are often chosen by small to mid-sized businesses that need more throughput or a larger marking field than a 5W can comfortably provide. Here’s what a 10W UV laser offers:

- Roughly 2× the Speed of a 5W: With double the power, a 10W UV can engrave the same design in a shorter time or achieve a stronger mark in one pass. For glass engraving, this means you can maintain decent speeds (~300–400 mm/s or more, depending on the glass and desired depth) while still getting a opaque frosted mark. If you were doing, say, 100 glass trophy plates with a company logo, a 10W will significantly cut down production time compared to a 5W. Both 5W and 10W can achieve similar quality (the wavelength and beam size are the same), but the 10W delivers higher energy per second, which you can leverage for either speed or slightly deeper engraving. In practice, users report that 5W and 10W both work well for glass, though 5W may require more fine-tuning, whereas 10W gives more latitude in settings.

- Water-Cooled Reliability: Most 10W UV laser machines are water-cooled, meaning they include an external chiller unit to keep the laser crystal and optics at a stable temperature. UV lasers at 10W generate more heat (since UV DPSS lasers are not very energy-efficient), and water cooling ensures you can run longer jobs or even continuous production without overheating. The water-cooled system adds a bit of complexity (a chiller box, coolant hoses) and typically these machines will be floor-standing or larger desktop units. The benefit is improved stability and potentially longer laser lifespan under heavy use. Haotian’s 10W UV model, for example, is offered as a water-cooled package and is aimed at users who need that mid-range endurance and consistency for daily operation. If you’re upgrading from a smaller laser or plan to use the machine several hours a day, investing in a 10W UV with proper cooling is wise.

- Larger Lenses & Marking Area: With more power, a 10W UV can handle larger lens options more effectively. You might use a 150×150 mm lens as the standard on a 10W (as opposed to 100×100 on a 5W). Some 10W systems can even go up to 200×200 mm or more marking field with the right lens. Keep in mind, as the lens F-theta focal length increases for a bigger field, the laser spot gets slightly larger and energy density lowers at the same power. But since you have extra power to spare, a 10W can still mark glass over a bigger area reasonably well. Example: If you want to engrave a graphic across a 200 mm glass panel in one go, a 10W will have an easier time maintaining a uniform mark than a 5W trying to stretch to that size. (The FSL guide on UV glass marking notes successful results even with a 254 mm lens on a 5W, but that’s pushing the limits. A 10W gives you a cushion in power to tackle bigger lenses or higher speeds when needed.)

- Ideal Use Cases: 10W UV lasers hit a sweet spot for small business production – e.g., an etching business personalizing champagne bottles, a manufacturer marking serial numbers on glass instrument panels, or a workshop doing varied custom jobs. The 10W can handle glass, crystal, and also common UV-friendly materials (plastics, acrylic, ceramic, etc.) with high precision. It’s still not a metal engraver (though it can mark coated metals or create surface marks on bare metals to a degree), but it excels at versatility on non-metals. The increased power also sometimes allows a 10W to do things like light cutting of thin materials (for instance, cutting thin plastic films or stickers without burning). If the 5W is a fine pen, the 10W is a thicker marker – covering more area faster but with the same level of control.

10W UV: Need more throughput or a larger working area for your glass engraving projects? The Haotian HT-10 10W UV laser might be your perfect mid-tier solution. This water-cooled UV engraver offers the stability for longer production runs and can cover bigger fields while maintaining the fine detail UV lasers are known for. With a 10W UV, you can efficiently tackle moderate-volume orders (like corporate gifts or product batches) without sacrificing quality. It’s a true workhorse for growing businesses – consider investing in a 10W UV to scale up your engraving capabilities with confidence in both speed and precision.

15W UV Lasers: High-End Performance for Industry

At the top end of UV laser marking power, 15W machines represent the cutting-edge of UV engraving performance in this class. These lasers carry a higher price tag but deliver faster processing and the ability to handle the most challenging applications. Here’s what sets the 15W UV laser apart:

- Fast and Efficient Marking: With 15 watts of UV power, you have three times the power of a 5W – this translates into markedly faster engraving on glass and other materials. A 15W UV laser can produce a deep, frosty mark on glass in fewer passes, or allow you to crank up the marking speed for higher throughput. This level of power is particularly valuable in an industrial setting where hundreds or thousands of parts might need marking. In such cases, a 15W UV can be integrated into a production line, marking each item in seconds. For example, the Haotian 15W UV model is described as delivering “top-tier performance for heavy-duty marking and engraving”, able to efficiently mark challenging surfaces such as glass, rubber, plastics, and metals at high speed. The extra power ensures even difficult materials like certain ceramics or composites can be marked with clear contrast, where a lower-power laser might struggle.

- Minimal Heat, Maximum Quality: Even at this higher power, UV lasers maintain their key advantage of minimal heat-affected zone. A 15W UV still operates at 355 nm, so it creates crisp, clean marks without compromising material integrity. This is crucial for applications in sectors like pharmaceuticals (marking glass vials or syringes), electronics (etching on delicate components), or aerospace (where parts must not be thermally damaged). The 15W UV’s ability to mark quickly yet gently makes it the go-to for high-end industrial marking where both speed and quality are non-negotiable.

- Water-Cooled & Industrial Build: All 15W UV lasers are water-cooled systems due to the heat they generate. They typically include a robust chiller and are built on heavy-duty frames to ensure stability. You’ll often find features like vibration damping, safety enclosures, and automated part feeders with these systems when used in factories. They are bench-top or floor-standing machines and require a bit of space and a proper environment (e.g., you wouldn’t run a 15W UV in a small unventilated room both for heat and a bit of ozone the UV beam can produce). These machines also come with longer duty cycle ratings – they’re meant to run all day. For instance, Haotian’s 15W UV laser comes with an 18-month warranty and is aimed at industrial use in sectors like aerospace, automotive, electronics, and packaging. In short, 15W UV lasers are production-grade equipment.

- Larger Lenses and 3D Options: A high-power UV laser can make better use of large-format lenses. You can pair a 15W with a 210×210 mm or even 300×300 mm lens to mark larger items or trays of parts in one pass. The power helps ensure the markings at the extremities of the field are still clear. Moreover, many 15W UV systems can be upgraded with a 3D galvo head (more on 3D heads in the next section) to allow focusing over curved surfaces or varying heights. In fact, Haotian offers an upgrade to a 3D Feeltek dynamic focusing head for its UV lasers – this can be especially useful for 15W systems, as you might be tackling complex objects at this tier. If your work involves engraving on not-flat surfaces (like cylindrical glass bottles or curved acrylic panels) at high volumes, a 15W UV with a 3D head ensures you get uniform results across the entire surface.

- Cost Consideration: It’s worth noting that UV lasers are more expensive per watt than fiber or CO2 lasers due to the complexity of generating the UV beam (they use specialized crystals for frequency tripling). A 15W UV is a significant investment – often two to three times the cost of a fiber laser of equivalent power. However, if your business needs the unique capabilities of UV (fine, cold marking on sensitive materials), the investment pays off in being able to offer premium services and high precision. The 15W UV essentially enables you to do jobs that others simply cannot match in quality.

15W UV: For industry-leading precision and speed, the Haotian HT-15 15W UV Laser stands at the top. This water-cooled, high-power UV engraver can tackle large-scale projects and demanding materials with ease – from rapid glass etching on an assembly line to ultra-fine marking on electronics and medical devices. If you’re looking for the ultimate UV laser performance to boost your production capabilities, the 15W UV is the solution. Invest in a 15W UV laser to achieve unparalleled quality and throughput, and stay ahead of the competition with cutting-edge “cold” marking technology.

3D Galvo Heads for Curved Glass and Complex Objects

Engraving flat glass plates is one thing, but what if you want to laser-etch a wine glass, a mug, or an intricate 3D shape? This is where 3D galvo heads come into play. A 3D galvo head (such as those made by Feeltek) adds a dynamic third axis (usually a moving lens or mirror) to the laser marking system, allowing the focal distance to change on the fly. In simpler terms, a 3D head lets the laser maintain focus over a range of depths, rather than just a flat plane.

Why is this important? Imagine engraving around a curved glass, like a drinking glass or bottle.

With a standard 2D galvo, the laser is focused on one plane – as soon as the surface curves away, the laser spot goes out of focus, and the engraving can become faint or blurry. Traditionally, you’d address this by mounting the object on a rotary axis, spinning the round object so that the area under the laser is always flat relative to focus. A rotary works, but it only handles simple cylindrical shapes (and adds mechanical motion that can slow the process).

A 3D galvo head can do this without a rotary, by automatically adjusting the focus depth as it scans across the curved surface. For example, if you wanted to engrave a continuous pattern around a glass tumbler, a 3D head could tweak the focus for the slight curvature top to bottom, achieving an even mark all around.

For complex objects or varying height surfaces, 3D heads are game-changers. They enable:

- Curved Surface Engraving: You can mark domed glass awards, convex lenses, or even concave shapes. With the proper software (like EZCAD3 or similar that supports 3-axis control), you import or define the surface geometry and the laser’s focus dynamically follows that shape. Feeltek’s 3D galvanometer systems are known for this capability – they can map a Z height for every X,Y coordinate, essentially “sculpting” the laser’s focal point to the object. The result is uniform engraving depth and clarity across the curve.

- Deep 3D Engraving (Relief): A 3D head can also be used to do 2.5D or 3D relief engravings on a flat surface by varying the focus to carve depth. This is more commonly done in metals with fiber lasers, but it could be applied to glass or crystal for creative effects (for instance, engraving a 3D landscape inside a block of glass by removing material in layers). The HT-5 3D Inner Crystal model by Haotian is an example – it’s a 5W UV laser with a 3D head configured specifically to etch inside transparent crystal blocks, creating 3D images (similar to those subsurface laser crystal portraits). The UV’s small spot size actually makes it quite suitable for internal glass engraving when tightly focused inside the material.

- Tolerance for Uneven Surfaces: In real-world scenarios, not every part is perfectly positioned or flat. A 3D galvo can compensate for small height variations. For example, if you are engraving on glass panes that might have slight warping or on assembled products with multiple levels, the 3D head can adjust within a certain range (say ±10 mm or more, depending on the optics) to keep the beam on target. This reduces the need for extremely precise fixturing.

Using a 3D galvo head does require more sophisticated software and calibration (you need to either scan the surface or have a CAD model of it to input). Software like EZCAD3 is designed to work with 3-axis control and is commonly supplied with systems like the JPT M8 or the 3D Feeltek setups. Haotian provides EZCAD3 with their 2.5D/3D-capable machines, allowing advanced users to leverage these features out of the box.

It’s also worth noting that 3D heads can increase your marking area even on flat work. They often come with larger aperture optics and can project the laser over bigger fields (since they can correct field curvature). So sometimes a 3D head is used not only for actual 3D surfaces, but to get, say, a 300×300 mm flat marking area with consistent focus.

3D Upgrade: If you plan to engrave a lot of curved or irregular glass objects – such as bottles, cylindrical gifts, or even internal 3D images in crystal – consider upgrading to a 3D galvo head. Haotian offers 3D Feeltek head upgrades on their UV lasers, which can transform your machine into a truly versatile engraver for both flat and curved surfaces. By investing in a 3D head, you’ll expand your capabilities to new applications (and impress clients with engravings that wrap around or appear inside the material!). It’s an upgrade that can set your services apart, especially in the custom glass engraving market.

Beyond Glass: Materials You Can Engrave with a UV Laser

One of the biggest advantages of UV laser engravers is their flexibility in marking a wide range of materials, especially those that are sensitive to heat. If you invest in a UV laser for glass, you’re not limited to just glass – you can take on many other projects. Here are some materials and examples of what a UV laser (5–15W) can do:

- Plastics and Polymers: UV lasers are superb for plastics because the 355 nm wavelength is often readily absorbed by plastics that might be transparent or reflective to other wavelengths. You can mark acrylic, polycarbonate, ABS, PVC, PET, polyurethane, and many others. Unlike a fiber laser which might melt or burn plastic (leaving a rough or raised mark), a UV laser’s cold marking can produce a smooth, high-contrast mark without burning. For example, UV lasers are used to mark white or clear plastics with a frosty logo or text (where a fiber wouldn’t leave a visible mark). They’re common in electronics for marking cases, connectors, and circuit boards (UV can remove solder mask on PCBs very precisely). If you make custom acrylic art or personalized plastic tags, a UV laser allows fine detail without melting the edges. (Note: When marking certain plastics like PVC, always ensure proper fume extraction, as the laser will still release fumes – the benefit of UV is the mark looks clean.)

- Rubber and Silicone: UV lasers can engrave rubber stamps or silicone parts with excellent precision. The beam vaporizes the material with minimal heat spread, so you get clean, sharp edges on stamp patterns or gasket engravings. For instance, a Haotian 5W UV was shown engraving fine details on rubber without charring. This is a niche where UV outperforms CO2 – a CO2 laser can cut rubber, but it often leaves a melted or tacky surface. UV lasers ablate rubber more like a sanding process, leaving a matte, ready-to-ink finish for stamps.

- Ceramics and Stone: Certain ceramics (especially glazed ceramics) and stones like marble or granite can be marked by UV lasers. The high energy can cause a localized change in the glaze or stone surface, often turning it white. For example, you could mark a black ceramic tile with a permanent white mark using a UV laser – the contrast can be quite striking. Stone and ceramic don’t conduct heat well, so UV’s low heat method reduces the chance of cracks. Keep in mind, for deep engraving in stone, a higher power or multiple passes will be needed and it’s slower than a CO2 would be on stone. But for fine marking (like a small text or intricate logo on a ceramic piece or on a piece of jewelry like jade), UV does a very neat job.

- Glass and Crystal: We’ve covered glass extensively – it’s the flagship material for UV. But to reiterate, UV lasers can mark not only flat glass but also crystal, tempered glass (with caution), mirrors (on the glass side without popping the silvering), coated glass, etc. One application is in the luxury industry: UV lasers mark serial numbers on watch glass or etch small logos on crystal awards with a clarity that looks almost printed. They can also do internal engraving in certain clear materials when using a 3D focus (creating those floating 3D images inside crystal blocks).

- Metals (Certain Cases): UV Galvo lasers can mark and engrave steel with impressive precision, especially when it comes to detailed photo engraving or fine surface marking. While UV lasers aren't designed for deep engraving into raw metal like fiber lasers, they excel in producing crisp, high-contrast marks—perfect for logos, images, serial numbers, and decorative patterns on stainless steel and coated metals.

Our 15W UV Galvo, for example, can gently etch steel surfaces without overheating or distorting the material, making it ideal for light-duty metal marking where precision and surface quality matter most. This is particularly useful for applications like engraving photos on steel tags, marking anodized or coated aluminum, or even adding surface detail to reflective metals like gold, silver, or copper.

- Organic Materials (Wood, Paper, Leather): UV lasers are not commonly used on wood or leather because they are slower and the marks are usually very light (the UV tends to bleach or slightly ablate organics rather than burn). However, you can engrave them. For example, a UV laser can mark paper or cardstock with extremely fine detail (like security printing or intricate invitations) with almost no burn-through. It essentially discolors the paper or slightly etches it – something a CO2 would likely char. On leather, a UV might make a subtle mark without the charred edges, useful for very fine patterns. On wood, UV engraving will make a light-colored mark (not the dark burn mark a CO2 produces). This could be useful for scenarios where you don’t want any scorch, though the contrast is low. So while UV lasers can engrave these, if your primary work is wood cutting or leather engraving, a CO2 is far more efficient. Think of the UV’s use on organic materials as specialized (e.g., engraving a company logo in the pages of a book or marking a design on a fabric without burning it – yes, UV lasers can mark certain fabrics and not burn holes because of the low heat).

In summary, UV lasers are extremely versatile. Plastics, glass, ceramics, rubber, and more – all can be addressed with one machine. This versatility is a huge plus for small businesses or makers who do custom jobs on all kinds of materials. You can confidently accept projects knowing the UV laser can likely mark the item cleanly. The only major materials UV can’t handle well are thick metals (where fiber wins) and large-scale wood/acrylic cutting (where CO2 wins). For marking and engraving purposes, UV covers a broad spectrum.

UV lasers are well-suited to a wide array of materials. They excel at marking heat-sensitive substrates like plastics, fabric, rubber, and of course glass, producing crisp results without burning or warping the workpiece. Even metals can be marked in some cases with a UV laser’s high peak energy, though for deep metal engraving other laser types are preferred.

JPT M8 Fiber Lasers (100W & 120W) for Glass cutting and More

Shifting gears, let’s discuss the JPT M8 fiber laser models (100W, 120W) and their capabilities, especially as they relate to glass processing. Fiber lasers are very different beasts compared to UV lasers: they operate in the infrared (1064 nm), and they are typically used for metal engraving, cutting, or high-speed marking. However, the JPT M8 series is a high-power, MOPA-based fiber laser that has some unique tricks, making it relevant to our topic in two main ways:

- It’s a powerhouse for deep engraving and cutting (including glass cutting).

- It requires advanced control software (EZCAD3) and often comes with 2.5D/3D functionality, allowing things like dynamic focus and relief engraving.

What is the JPT M8 Fiber Laser?

JPT is a well-known manufacturer of laser sources, and their MOPA fiber lasers are highly regarded for stability and pulse control. The M8 series specifically refers to higher power units – 100W, 120W, up to 200W – that are often used in fiber laser marking machines aimed at heavy-duty tasks. Unlike a continuous-wave fiber laser (used in big metal cutters), these are pulsed lasers that can still reach very high peak powers. For instance, the 100W/120W M8 can produce pulses with up to 100 kW peak power in a very short burst. That high peak power, combined with a decent beam quality (<1.5 M2), is what allows the M8 to perform processes like glass drilling. Essentially, when that energy is tightly focused, it can cause a microscopic portion of the glass to vaporize or fracture, even though the wavelength is not absorbed well by glass in continuous mode. By pulsing with enormous intensity, the M8 forces absorption via nonlinear effects and the sheer thermal shock.

Key features of M8 fibers:

- High Pulse Energy & Peak Power: As mentioned, ~100,000 watts peak (for comparison, a typical 20W fiber has maybe 8-10 kW peak). This is why M8 can do things like perforate glass or etch deep into metals quickly. The pulse duration is also adjustable (in the nanosecond range, e.g., 2–50 ns), which is a hallmark of MOPA – you can tailor the pulse width to the material. Short pulses, high energy tend to crack glass in a controlled way; longer pulses might anneal mark or engrave more slowly.

- High Average Power (100–120W): With 100+ watts average, these lasers can sustain processes like deep metal engraving or thin metal cutting. For example, you could cut small shapes out of 1 mm stainless steel or brass using a 100W fiber laser marking system (slower than a true fiber cutter, but feasible for small pieces like jewelry). Advertisements for 100W fiber markers highlight tasks such as cutting custom jewelry nameplates, deep engraving molds or coins, and even mirror-like polishing of marks by fine pulse control.

- EZCAD3 and 2.5D Capabilities: The M8 systems are usually paired with EZCAD3 software (since EZCAD2 tops out at 2 axes and lower power). EZCAD3 opens up advanced features like 3D engraving, height mapping, and more robust control of the laser parameters. Many 100W+ fiber machines include a motorized Z-axis tower (for focus) and sometimes a dynamic focus lens if 3D engraving is intended. For instance, Haotian’s HT-120 fiber laser comes with a heavy-duty motorized Z column and can be used for 2.5D engraving. “2.5D” typically means it can do relief engraving by varying focus slightly (not fully dynamic like a 3D galvo, but moving between layers), which EZCAD3 supports. So, the M8 is not just brute force; it’s also a finely controllable tool for detailed work in 3 dimensions on metal or other materials.

Now, how does this relate to glass?

The manufacturer literature positions these high-power fiber lasers as capable of glass drilling, cutting, and engraving, which is unusual for fibers. But as we described, the method is different from UV. Instead of gently etching the surface, the fiber M8 uses pulses to drill through the glass or scribe lines that then can be broken out. Let’s break down what an M8 fiber can do with glass:

- Drilling Holes in Glass: With a focused 100W M8 fiber, you can drill small holes in glass surprisingly fast. Tests show the M8 can drill, for example, a 2 mm diameter hole through 1 mm thick glass in a second or two, and even larger holes with a bit more time. A sample test from Haotian with a 100W M8 listed drilling a 10 mm diameter hole in 1 mm thick glass in about 1.9 seconds, and a 10 mm hole in 5 mm thick glass in about 6.1 seconds. That’s extremely fast – something a UV laser could never achieve (UV would be limited to surface marking, not full penetration). This makes the M8 attractive for applications like creating vent holes in glass, processing glass wafers (for electronics), or any scenario where you need clean holes or cut-outs.

- Cutting Out Shapes: By combining drilling and motion, an M8 can cut shapes out of glass. Essentially, the laser can be used to trace a path on the glass (often multiple passes) to create a stress line, then the piece can be separated. In some cases, the laser can fully cut through if it goes slowly and uses the dynamic focus (for thick glass, a bit of mechanical separation after scoring is common). The Haotian demo for the 100W/120W M8 shows it as a “fiber laser glass cutting machine”. They note it’s especially suitable for tasks requiring high peak power and brightness, like glass drilling. With the right setup (usually involving a 3D head or specialized optics), you could cut something like a 50 mm circle out of a glass sheet. The edge quality won’t rival a waterjet or a CO2 laser on thin glass (CO2 with a coaxial air/water assist can cut thin glass with smoother edges), but the fiber’s advantage is no consumables and very precise control in small areas.

- Engraving or Marking Glass: A fiber M8 can mark glass, but the mark will appear different from a UV’s frosted surface. Fiber laser marks on glass often look like small cracks or a “shot peen” effect – a series of tiny frosted dots where the laser pulses impacted. It can be used to create a frosted appearance, but it may not be as uniform as a UV laser’s mark. It’s more similar to sandblasting or using a diamond engraver. For instance, if you just want to put a serial number on a piece of glass, a fiber could do it by essentially peppering the surface. The M8, having high pulse energy, can do this more effectively than a low-power fiber (which might not mark at all). That said, if one’s goal is a visually perfect logo or photo on glass, the UV laser is the appropriate tool. The fiber’s marking on glass is usually reserved for when you already have a fiber for other reasons and want to do a utility mark on glass without buying a second machine. Use case: A factory that primarily laser-marks metal tools might occasionally need to mark a glass gauge – the 120W fiber could put a scale or number on it sufficiently.

- Mixed Material Capability: One cool aspect of a high-power fiber like the M8 is you could do projects involving multiple materials. Say you have a product that’s metal but has a glass component – the fiber can mark the metal deeply and also mark or cut the glass component. It provides a one-machine solution for such hybrid tasks. Also, since fiber lasers can mark many plastics (usually with a discoloration or foaming effect) and can even mark some organic materials (it will burn them though), an M8 is quite versatile in a workshop, albeit with more heat than a UV. For example, the fiber can engrave coated metal tumblers, cut acrylic (if it’s a dark acrylic that absorbs 1064 nm), and mark certain plastics. It’s not as clean on plastics as UV, but sheer power can sometimes compensate. The fiber’s strength, however, remains metal. With 100–120W, you can do things like engraving mold inserts to create cavities, making embossing stamps, cutting thin sheet metal parts, and annealing or etching steel with high contrast. A 120W MOPA fiber can even attempt color marking on stainless steel by finely tuning pulse frequencies and durations (though lower power MOPA like 30W are more commonly used for color, the 120W could do it very fast if controlled).

Full Review of M8 Capabilities for Glass and More

Let’s summarize the M8’s capabilities in a more list-oriented review:

- Metal Engraving (Deep): Excellent. The M8 can engrave deeply into metals like steel, brass, aluminum, etc., much faster than lower power lasers. It’s suitable for 3D engraving (relief) in metal to create molds or coins. For instance, a deep 3D relief that might take a 20W fiber 10 passes could be done in 2-3 passes with a 100W M8. The beam quality is good enough for fine details even at depth. Industrial examples include engraving firearm parts, mold dies, or automotive parts with serialization.

- Metal Cutting: Good for thin materials. The M8 (100–120W) can cut sheet metals up to a certain thickness (roughly 1 mm for steel, possibly 1.5 mm for brass or thinner metals). It won’t replace a 500W fiber laser cutter for thick plate, but for small precision cutouts (jewelry, electronic components, watch parts) it’s very useful. Being a marking machine format, it usually has a smaller bed and galvo head, so think small items rather than large sheet cutting.

- Glass Drilling/Cutting: Excellent in its niche. It’s one of the few lasers that can truly cut through glass in a controlled way. For drilling holes, it’s extremely fast and precise (holes as small as the laser spot ~0.1 mm possible, up to larger holes by spiral motion). For cutting, it’s effective on thinner glass; thicker glass (e.g., >5 mm) can also be cut but might need slow multi-pass and the edge will be rough. The M8’s ability to maintain beam quality at high power (not diverging too much) is crucial for focusing into glass to do these tasks.

- Precision and Spot Size: The spot size of a fiber laser is usually on the order of 30–50 microns with a standard lens (say 110×110 mm area). The M8, with <1.5 beam parameter, focuses fairly tightly. However, UV lasers can achieve even smaller spots (~10–20 microns). So for the finest micro-detail, UV still wins. The M8 is precise, but it’s more like using a sharp chisel versus UV’s fine needle. If you needed to engrave a microscopic QR code on glass, UV would do it; the fiber M8 might struggle to get the same clarity due to slightly larger spot and the nature of how it marks glass (micro-cracks).

- Software and Ease of Use: These high-power systems come with advanced software that has a learning curve. EZCAD3, while powerful, is known to be less intuitive than LightBurn or other user-friendly software. However, it’s required for the 3-axis control and for unlocking things like multi-layer engraving, true 3D, etc. Haotian’s HT-120 fiber machine includes EZCAD3 original (not a stripped version) and even supports LightBurn for basic operations. That means you could do simple jobs in LightBurn and switch to EZCAD3 for complex ones. Technical support is key here – ensure you have training or documentation especially if using the 2.5D features.

- Maintenance: Fiber lasers, in general, are low maintenance (no alignment of mirrors, etc.), and the M8 is no exception. It’s basically a sealed laser source and a scanning head. Water cooling is required for the head or laser if running at full power continuously (Haotian’s specs include a chiller for the 120W unit). Expect a chiller similar to those on CO2 lasers but sized for maybe 1–2 kW of heat removal. Keep the optics clean (dust on the galvo mirrors or lens is bad news when 100W pulses hit them!). But you won’t be replacing tubes or lamps like other lasers – these fiber sources are rated for ~50,000+ hours.

In essence, the JPT M8 fiber lasers turn your operation into an all-materials engraving and cutting shop. They complement a UV laser perfectly: you would use the UV for the super fine and delicate work, and the fiber for heavy lifting and deep cutting. In fact, many businesses that engrave a variety of items end up with both a fiber and a UV machine to cover all bases. If budget allows, this combo means no job is out of reach – metals, glass, plastics, all can be handled.

100W/120W M8 Fiber: If your business involves not just glass, but also metals or high-volume production, consider adding a Haotian HT-100 or HT-120 fiber laser with JPT M8 source to your toolkit. These machines bring incredible power and speed, enabling you to cut and engrave metals (and even perform glass drilling and cutting) with ease. Equipped with EZCAD3 and available in 100W or 120W models, Haotian’s M8-powered fiber lasers can dramatically expand your capabilities – from deep engraving steel molds to cutting intricate jewelry and drilling glass wafers. For professionals aiming to offer a one-stop solution for clients, the investment in a high-power fiber laser is a strategic move that can pay off with new business opportunities and faster workflow.

Choosing the Right Laser Machine for Your Glass Projects

Now that we’ve covered the spectrum of laser technologies – from UV lasers of various strengths to high-power fiber lasers – how do you decide which one is right for you? The choice will depend on what you plan to do (types of products, materials, and designs) and your budget. Let’s break down a few scenarios and recommendations:

- Hobbyist or Home Business (Custom Gifts, Low Volume): If you’re primarily engraving glassware (like mugs, wine glasses, ornaments) or small acrylic/plastic items as a side business or hobby, a 5W UV laser is often the best entry point. It provides professional-quality results on glass that will set your work apart (remember, UV engraving on glass is much finer and smoother than what cheap hobby lasers or rotary tools can do). You can also use it on plastics, leather, and more for various crafts. While slower, at this stage volume isn’t huge, so speed is less critical. The 5W UV’s lower cost and simpler setup (air-cooled, runs on standard power) make it manageable in a home or small workshop. Recommended model: Haotian HT-5 UV (5W) – it’s compact and comes with everything you need to get started, including a rotary for glasses and an entry-level price point.

- Growing Small Business (Higher Volume Gifts, Medium Runs): If orders are picking up and you find the 5W UV is becoming a bottleneck, it’s time to upgrade to a 10W UV. This will nearly double your throughput and allow larger designs. It’s also a good choice if you start doing projects that push the size limit of the 5W’s comfortable marking area. For example, etching a 200 mm glass award or batches of parts in one go. The 10W will handle that with less compromise on quality or needing multiple passes. It also gives you some headroom to explore materials that benefit from more power (like slightly deeper engraving on crystal or faster marking on harder plastics). Recommended model: Haotian HT-10 UV (10W) – a water-cooled UV laser that offers a balance of power and cost, ideal for a small business stepping up their production. It will come with the necessary chiller and likely a couple of lens options; with a 10W you might use a 150×150 lens as standard and a smaller one for ultra-fine work as needed.

- Industrial or High-End Engraving Service (Large volume, demanding jobs): If you’re servicing corporate clients, doing large batches, or need the absolute best quality for luxury products, a 15W UV laser is the way to go for glass and delicate materials. It gives you the speed to fulfill big orders on time and the confidence that you can mark just about any tricky material (from pharmaceutical glass to high-end cosmetics packaging) without damage. Additionally, if you foresee engraving complex shapes or needing to do 3D surface engraving, opt for the 3D galvo head upgrade at this tier. The investment is higher, but so is the return – you can take on specialized projects like engraving on curved crystal surfaces or inside glass blocks, which commands premium pricing. Recommended model: Haotian HT-15 UV (15W) with optional 3D Feeltek head. This setup equips you to handle anything from flat panel marking to wrap-around engravings, all at production-grade speed and precision.

- Mixed Material / Metal-Intensive Work: If your business is not just glass but also involves metals (and you want to expand into offerings like custom metal tags, knives, jewelry, or industrial part marking), then adding a fiber laser is a smart move. For primarily metal work with occasional glass, a 100W fiber (M8) could be your primary tool, and you might use a smaller UV only for when you need that extra finesse on glass or plastic. However, since our focus is glass, one strategy is: have a UV laser for glass and non-metals, and a fiber laser for metals and heavy-duty tasks. If budget allows only one high-end machine and you need to tackle both domains, the fiber laser (100W+) will cover more ground overall (metals + some glass ability), whereas a UV will leave you unable to do much on metals. So, for a shop that wants to say “yes” to almost any job, a combo of UV and fiber is ideal. Recommended model: Haotian HT-120 M8 Fiber (120W) for the heavy stuff. With its 120W power, you get blazing fast metal engraving and the unique ability to cut and drill glass up to decent thickness. Pair that with, say, a 5W or 10W UV for the ultra-fine detail work on glass/plastics that the fiber can’t match. Many businesses find that having both opens up maximum flexibility – you can always use the “big gun” fiber for rough work and the UV for finishing touches.

- Budget vs. Capability: It’s important to align your purchase with the kind of jobs you expect. If glass engraving is a side offering and 90% of your work is metal, prioritize the fiber laser first, since you can always outsource occasional glass jobs or add a UV later. Conversely, if you’re all about glass gifts and perhaps some acrylic or wood, the UV laser is the priority – you likely don’t need a high-power fiber immediately. Some mid-level fiber lasers (20-30W) are quite affordable and can mark metals, but they absolutely won’t work on glass; meanwhile, a UV laser can mark some metals (with limitations) and all your glass/plastic needs. So think about short-term needs and long-term plans. The good news is lasers hold value well, and as your business grows, you can often justify the next machine by the expanded services it allows.

Finally, whichever machine you choose, consider factors like support and training, especially for advanced systems like those with EZCAD3 3D features. Haotian and similar reputable suppliers often provide lifetime technical support, which is invaluable when you’re learning how to optimize settings for glass or trying a new material. Make sure to take advantage of those resources – they can shorten your learning curve significantly.

Recommendation Table – Laser Machines for Glass Engraving & Cutting

To help summarize the discussion, here’s a comparison of recommended laser machines from Haotian for various needs, highlighting their key specifications and ideal use cases:

Laser Machine Type & Power Cooling Best For Key Benefits

| Haotian HT-5 UV | UV Galvo, 5W @ 355 nm | Air-cooled | Hobbyists, custom gifts, fine detail | Lowest cost UV; ultra-fine engraving on glass/plastics; plug-and-play setup; ideal for precision work on small items. Limit: slower on large jobs |

| Haotian HT-10 UV | UV Galvo, 10W @ 355 nm | Water-cooled | Small business, moderate production | Mid-level power for faster engraving; handles larger marking areas; stable for longer runs with chiller. Great balance of speed and detail for growing businesses. |

| Haotian HT-15 UV | UV Galvo, 15W @ 355 nm | Water-cooled | Industrial, high-volume & tricky materials | High-end UV with fastest marking on glass; minimal heat damage even on sensitive materials; can be paired with 3D head for curved surfaces. Suited for continuous use in production environments. |

| Haotian HT-100 M8 Fiber | Fiber Galvo, 100W @1064 nm (JPT M8 MOPA) | Water-cooled | Metal engraving/cutting + some glass drilling | Powerful multi-purpose laser; deep engraves and cuts metals (fast), can drill/cut glass with high peak power comes with EZCAD3 for 2.5D work. Perfect if metal work is primary but glass capability is needed occasionally. |

| Haotian HT-120 M8 Fiber | Fiber Galvo, 120W @1064 nm (JPT M8 MOPA) | Water-cooled | Advanced industrial use – metals & glass | Top-tier fiber for maximum throughput; handles heavier metal jobs and slightly thicker glass cutting. High peak power (100+ kW) suitable for specialized tasks and quickest production times. If you want one machine to do (almost) it all, this is it – just note it doesn’t match UV on fine glass detail, but it covers everything else. |

(All the above machines include galvo scanning heads. UV models have approximately 0.01–0.03 mm spot size for fine detail, and fiber M8 models have ~0.03–0.05 mm spot allowing fine marks and cuts. Working areas are lens-dependent: e.g., 100×100 mm standard, up to 300×300 mm optional on UV, and typically 110×110 mm standard on fiber with larger lens options available. Each comes with needed software and support. Haotian UV lasers include accessories like rotary tools for glassware, and Haotian fiber lasers come with motorized Z for focus. Warranty is typically 1.5–2 years on these systems

Conclusion & Next Steps

Choosing the right laser for glass engraving and cutting comes down to understanding your application and matching it with the machine’s strengths. UV lasers (5W, 10W, 15W) are unparalleled for engraving glass and other heat-sensitive materials with precision – they leave smooth, frosted marks without cracks, making them the go-to for quality etching on glass, crystal, plastics, and more. Meanwhile, the JPT M8 fiber lasers (100W/120W) bring brute force and versatility, enabling you to cut and deep-engrave metals and even tackle glass cutting or drilling tasks that UV lasers cannot do. Many successful engraving businesses use a combination of these tools to cover the full spectrum of customer needs.

If you’re serious about laser engraving as a hobby or business, investing in a reliable machine is key. Haotian Laser, offers a range of UV and fiber laser machines that cater to each tier of need – from the entry-level UV galvos to the high-power fiber systems. With strong customer support and included extras (like rotary attachments and safety glasses in bundles), we make it easier to hit the ground running with your new laser.

Before making your purchase, consider requesting sample tests or demos. For example, you might ask for sample engravings on a piece of glass or a material you commonly use – many manufacturers will do this to show the results you can expect. Seeing a 5W UV vs 15W UV vs fiber mark on glass can be very enlightening. Also factor in any local regulations (laser safety classes, ventilation needs for fumes, etc.) and ensure you have the proper setup to operate the machine safely.

Ready to elevate your glass engraving game? Whether you’re ordering your first 5W UV laser or upgrading to a robust 15W UV or 120W fiber, the right machine will unlock new creative possibilities and business opportunities.

Feel free to reach out to our team at Haotian Laser for expert advice on selecting a laser engraver that fits your needs – we’re here to help you succeed in all your laser engraving endeavors.